Here are 5 types of G-Code simulator that are all good in some situations. Some of them are okay, others are a waste of time. There are quite a few options for simulating your G-Code out there. The 5 Best G-Code Simulators for Machining and 3D Printing A good simulator provides a quick and easy way to achieve this. Hobbyists and professionals alike need a way to see a 3D printed item before they spend hours printing it. G-Code simulators have experienced a resurgence in popularity over recent years thanks to the rise of 3D printing. Without this, the only way to debug your program is to test it out on the machine itself… and by then it’s too late to avoid disaster. The basic purpose of a G-Code simulator is to give you a way to see how the machine tool will move. They range from simple simulators that output a single image of the tool path to complex tools that can detect collisions and plot the path in 3D.

G code cnc simulator software software#

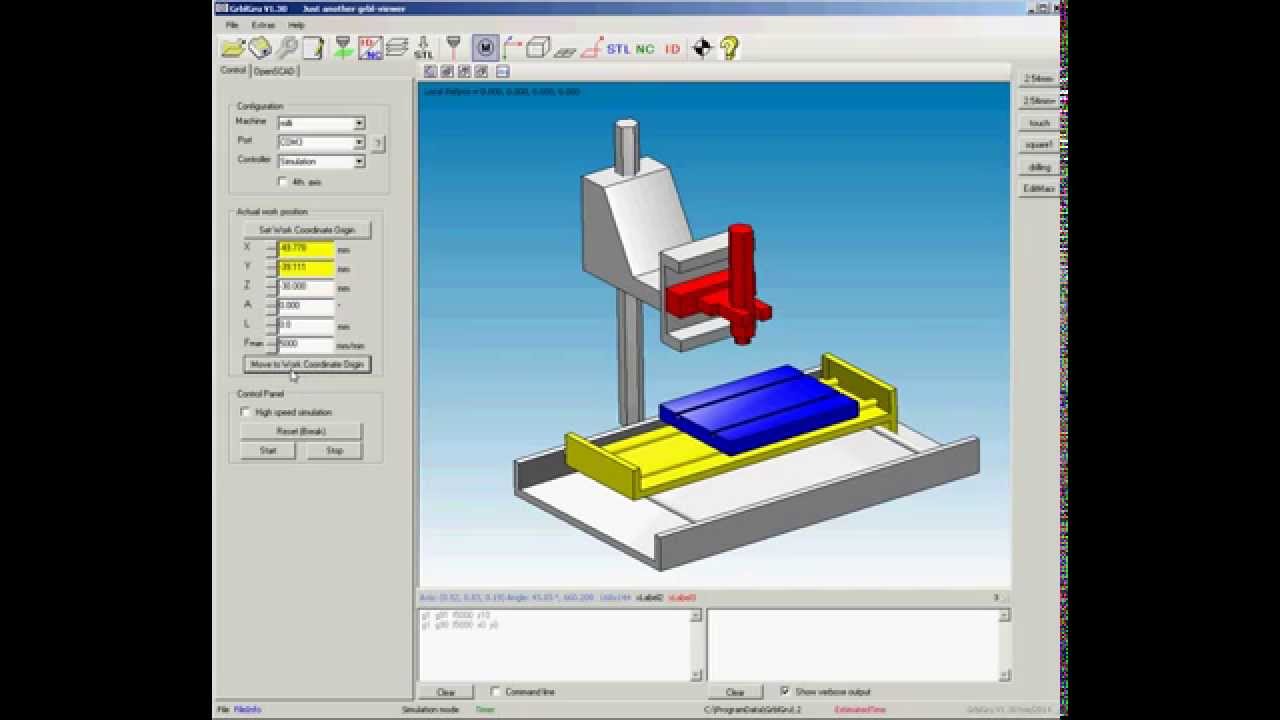

What is a G-Code Simulator?Ī G-Code simulator is a type of software tool that provides a virtual representation of a CNC machine’s tool path made by following the instructions in a G-Code file. Here is a list of some of the best types of G-Code simulator that you can use these days. Although very few people these days write G-Code by hand - we tend to use CAM programs - there is still a huge benefit to checking your program in a simulator before loading it into your physical machine.

G-Code simulation is probably the best way to ensure that you have written your program to a high standard. This is certainly true with programs that will interact with the physical world like those used to control CNC machines, 3D printers, and robotics.Īny mistake in the programming of these physical machines could cause real damage to the environment, the machine itself, and even to human workers in the case of some robots. Here are some of the best simulators.ĭebugging is a vital part of any programming task.

Module helps capture tool change, a module for drilling, tracing module screen fast, automatic numbering module blocks (N).A good G-Code simulator can make the difference between a successful manufacturing process or an expensive failure. This device allows beginners to read quietly and at any time a function and its usefulness.Īn Edit tab offers different modules for help writing your program. Because in fact manufacturers regularly create new languages and features to improve performance but also slightly to lock the learning of numerical control programming languages.Īs an encyclopedia that when you click on a word using the tab program offers help text for each address. Operating in the field of machine tools yet ultra-sensitive SIMUL CNC to democratize the simulator by making it universal. It provides a unique way to draw measures distance, angle, radius and threads directly on the path as a software computer aided design.Ī simulator CNC very useful for learners in training. Powerful software can communicate with other software, which avoids to enter the same information.Ī direct link is available in the definition of values with the software tools for managing cutting tools machining "Cutting Tool Manager."įunction quote request grip not necessarily obvious, especially if have become accustomed to other software.

G code cnc simulator software iso#

While ensuring the conservation of the shape of your original program this software will read and understand the functions associated with ISO G-Code program your CNC. The company offers Ange-Softs to reduce and simplify the action, using a CNC simulator to be universal. The 3D simulation of the work piece and cutting tool enable you to visualize the machining exactly as it occurs on the shop floor and corrects tool path errors before machining. You can evaluate the effect of the tool radius on your completed/finished part or simply take measurements from your finished part before cutting a single chip.Īll in all, even experienced machinists can also find ways to save money and time with Simul CNC. Use Simul CNC to ensure the tool won’t crash into your vise. Use Simul CNC to ensure that you’re getting the complete and best finish for a given machine time.

0 kommentar(er)

0 kommentar(er)